- Products

- Training

- Lindab Fire Damper Installation Course

- Fire Damper Testing and Inspection Training

- Grease Hygiene Technician Course (GHT) – BESA Short Course

- Grease Hygiene Operative (GHO) – BESA short course

- Air Hygiene Technician (AHT) – BESA Short Course

- Air Hygiene Operative (AHO) – BESA Short Course

- PASMA – Combined Towers for Users and Low Level Access

- Laboratory

- Contact us

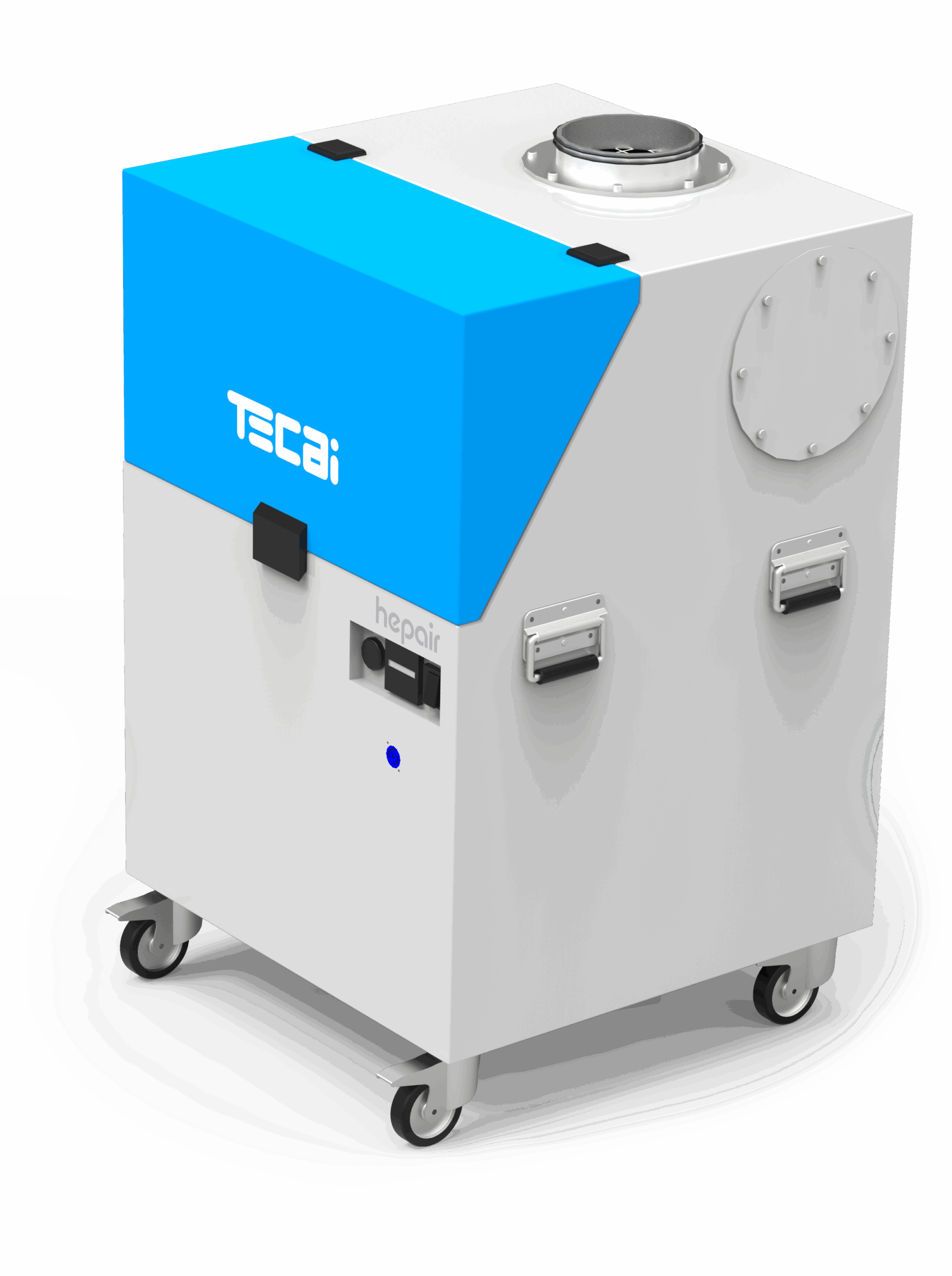

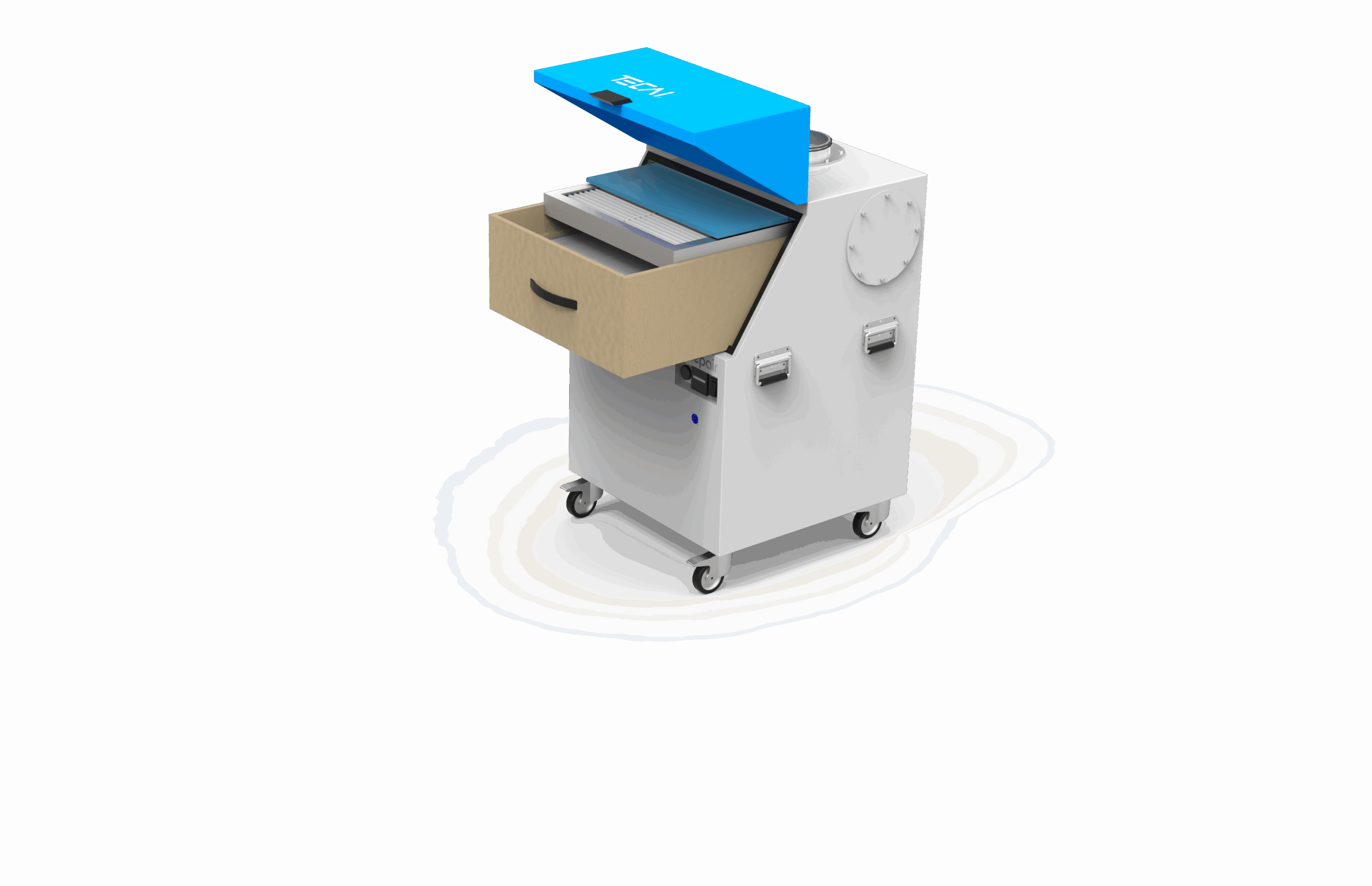

Tecai Hepair2000 – Dust Extraction Unit

POA

The Tecai Hepair 2000 is more than a vacuum. Its high performance places it as the workhorse of professional duct cleaning operations. The machine captures airborne particulates agitated by rotary brushing systems. This ensures that your cleaning process is effective, safe, and compliant. As a result, you can keep up with rigorous safety standards.

Powerful Negative Pressure and Airflow

The Hepair 2000 delivers an impressive airflow of 2000 m³/h. This creates a robust negative-pressure environment within the ductwork. Such suction power is critical for two reasons:

- Debris Extraction: The rotary brush loosens dust, heavy grease particles, and debris. This is where the extraction system comes in. It sucks all these deposits away from the cleaning zone and into the filtration unit.

- Contamination Control: Maintaining negative pressure prevents hazardous dust and spores from leaking out. It also prevents the contamination of the surrounding room. This is vital for working in sensitive environments. Such environments include hospitals, offices, and food production facilities.

Versatile Application Range

Designed for versatility, the Hepair 2000 is optimised for medium-to-large commercial ventilation systems.

- Duct Sizes: It services ductwork ranging from Ø200 mm to Ø800 mm. This covers the vast majority of standard commercial HVAC setups. As a result, it’s an essential “daily driver” for cleaning contractors.

- Easy Connectivity: The unit features a standard Ø160 mm hose connection. This allows for rapid setup and breakdown on-site. You can seamlessly connect to your existing ductwork access points or spigots.

Designed for TR19 Compliance

In the UK ventilation hygiene market, achieving TR19 compliance equates to quality. The Hepair 2000 assists in meeting these standards. It does this by ensuring that all particulate matter is removed from the system. This is instead of it simply being moved around. The extraction unit should be paired with a high-quality rotary brush machine. This pairing provides a “collect and contain” capability. Such is necessary for certifying a system as clean.

Key Features at a Glance:

- Max Airflow: 2000 m³/h for superior suction velocity.

- Operational Range: Ideal for circular and rectangular ducts equal to Ø200mm – Ø800mm.

- System Integration: The perfect companion for Tegras, Lifa Air, or other rotary brush systems.

- Portability: Designed for site mobility. This allows technicians to position the unit close to the work area. The result is maximum efficiency.

| Weight | 80 kg |

|---|---|

| Dimensions | 61 × 59 × 95 cm |

Powerful Negative Pressure and Airflow

The Hepair 2000 delivers an impressive airflow of 2000 m³/h. This creates a robust negative-pressure environment within the ductwork. Such suction power is critical for two reasons:

- Debris Extraction: The rotary brush loosens dust, heavy grease particles, and debris. This is where the extraction system comes in. It sucks all these deposits away from the cleaning zone and into the filtration unit.

- Contamination Control: Maintaining negative pressure prevents hazardous dust and spores from leaking out. It also prevents the contamination of the surrounding room. This is vital for working in sensitive environments. Such environments include hospitals, offices, and food production facilities.

Versatile Application Range

Designed for versatility, the Hepair 2000 is optimised for medium-to-large commercial ventilation systems.

- Duct Sizes: It services ductwork ranging from Ø200 mm to Ø800 mm. This covers the vast majority of standard commercial HVAC setups. As a result, it’s an essential “daily driver” for cleaning contractors.

- Easy Connectivity: The unit features a standard Ø160 mm hose connection. This allows for rapid setup and breakdown on-site. You can seamlessly connect to your existing ductwork access points or spigots.

Designed for TR19 Compliance

In the UK ventilation hygiene market, achieving TR19 compliance equates to quality. The Hepair 2000 assists in meeting these standards. It does this by ensuring that all particulate matter is removed from the system. This is instead of it simply being moved around. The extraction unit should be paired with a high-quality rotary brush machine. This pairing provides a “collect and contain” capability. Such is necessary for certifying a system as clean.

Key Features at a Glance:

- Max Airflow: 2000 m³/h for superior suction velocity.

- Operational Range: Ideal for circular and rectangular ducts equal to Ø200mm – Ø800mm.

- System Integration: The perfect companion for Tegras, Lifa Air, or other rotary brush systems.

- Portability: Designed for site mobility. This allows technicians to position the unit close to the work area. The result is maximum efficiency.

| Weight | 80 kg |

|---|---|

| Dimensions | 61 × 59 × 95 cm |