- Products

- Training

- Lindab Fire Damper Installation Course

- Fire Damper Testing and Inspection Training

- Grease Hygiene Technician Course (GHT) – BESA Short Course

- Grease Hygiene Operative (GHO) – BESA short course

- Air Hygiene Technician (AHT) – BESA Short Course

- Air Hygiene Operative (AHO) – BESA Short Course

- PASMA – Combined Towers for Users and Low Level Access

- Laboratory

- Contact us

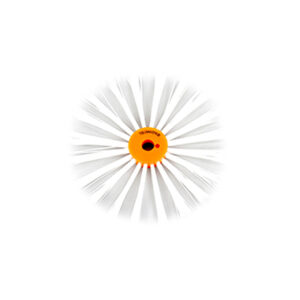

Tegras Extreme Grease Brush

£650.00

The Tegras Extreme Grease Brush is adjustable for cleaning the hardest grease deposits in duct sizes 300mm – 700mm. The brush is supplied with a carry case, required tightening tools, and multiple scratching blades to suit different ductwork diameters.

The Extreme Grease Brush is designed for the toughest cleaning and is compatible with Tegras’ brushing machines, Multipro, Forte, and Eon.

The Heavy-Duty Solution for Carbonised Grease

Standard nylon brushes are excellent for sweeping away soft, gelatinous grease. That said, they often struggle against rock-hard, baked-on deposits. These are often found in high-temperature extract systems. The Tegras Extreme Grease Brush is the definitive answer to this problem. It bridges the gap between standard rotary brushing and labour-intensive manual scraping.

Engineered for aggressive cleaning, this tool uses the high torque of Tegras machines. The torque strips away carbonised grease that other brushes leave behind. It is the ultimate accessory for tackling “burned” ducts. This works for steakhouses, burger chains, and industrial fryers.

Key Operational Benefits

- Slash Labour Times: The Extreme Brush reduces job duration and labour costs. This is because it removes hardened deposits. As a rule of thumb, these would demand hours of manual hand-scraping,

- Centrifugal Cleaning Power: As the brush spins, the blades expand via centrifugal force. From this, they apply consistent, hard-wearing pressure against the duct walls. This works to chip away stubborn residue.

- Cost-Effective Maintenance: The Extreme Grease Brush features replaceable scratching blades. This is unlike fixed-head wire brushes that you must discard when worn. From this, you ensure your running costs remain low while maintaining peak performance.

Versatility for Complex Systems

While designed for power, the unit remains adaptable. The adjustable diameter (300mm – 700mm) allows a single tool to clean ducts of varying sizes. This is without stopping to change equipment. The Extreme Brush ensures you can achieve a TR19® compliant bare-metal finish. You can even do so for the most neglected systems. This is true whether you are cleaning rectangular or circular steel ductwork.

Note: Due to the tool’s aggression, we recommend it for heavy-gauge steel ductwork. It is not suitable for flexible ducting or delicate internal linings.

The Heavy-Duty Solution for Carbonised Grease

Standard nylon brushes are excellent for sweeping away soft, gelatinous grease. That said, they often struggle against rock-hard, baked-on deposits. These are often found in high-temperature extract systems. The Tegras Extreme Grease Brush is the definitive answer to this problem. It bridges the gap between standard rotary brushing and labour-intensive manual scraping.

Engineered for aggressive cleaning, this tool uses the high torque of Tegras machines. The torque strips away carbonised grease that other brushes leave behind. It is the ultimate accessory for tackling “burned” ducts. This works for steakhouses, burger chains, and industrial fryers.

Key Operational Benefits

- Slash Labour Times: The Extreme Brush reduces job duration and labour costs. This is because it removes hardened deposits. As a rule of thumb, these would demand hours of manual hand-scraping,

- Centrifugal Cleaning Power: As the brush spins, the blades expand via centrifugal force. From this, they apply consistent, hard-wearing pressure against the duct walls. This works to chip away stubborn residue.

- Cost-Effective Maintenance: The Extreme Grease Brush features replaceable scratching blades. This is unlike fixed-head wire brushes that you must discard when worn. From this, you ensure your running costs remain low while maintaining peak performance.

Versatility for Complex Systems

While designed for power, the unit remains adaptable. The adjustable diameter (300mm – 700mm) allows a single tool to clean ducts of varying sizes. This is without stopping to change equipment. The Extreme Brush ensures you can achieve a TR19® compliant bare-metal finish. You can even do so for the most neglected systems. This is true whether you are cleaning rectangular or circular steel ductwork.

Note: Due to the tool’s aggression, we recommend it for heavy-gauge steel ductwork. It is not suitable for flexible ducting or delicate internal linings.